Product Innovations

Fast Retailing is committed to producing high-quality items, and to pursuing sustainability in our clothing and processes. These are the latest developments.

Photo:KinyaOta

UNIQLO

We use recycled polyester material made from post-consumer PET bottles to support the more efficient use of resources. This year, recycled polyester comprises 32% to 75% of the high-performance, quick-drying DRY-EX Polo Shirt, and 30% of the Fluffy Yarn Fleece Full-Zip Jacket, and Fluffy Yarn Fleece Pullover Shirt.

As the first initiative of product-to-product recycling under our RE.UNIQLO

program, we launched our Recycled Down Jacket in November 2020. This item is filled completely with reclaimed down and feathers taken from pieces of 620,000 down products collected in Japan since the start of 2019. The recycling process uses a completely automated down-separation system newly developed by Toray Industries, Inc. The system offers approximately 50 times the processing capability of manual processes, and has enabled large-scale recycling and production. The down and feathers are washed after separation, and those that meet the criteria for cleaning as new ones are recycled as materials to be used in new down products.

Theory

'Good Wool' products are part of a signature program in 'Theory For Good', the brand's platform for social and environmental responsibility. The 'Good Collection' is consciously designed to make a positive impact on our communities and the planet. Here, the 'Good Wool' is shown in ultra-fine merino wool sourced from responsibly-raised Australian sheep and woven in Italian mills using the latest energy and water-saving technologies.

GU

We aim to create jeans with a low impact on the environment. We have reduced water consumption by up to 96%* in the finishing process by reviewing and improving upon the conventional production process. This processing method is used for all GU jeans such as the Tapered Ankle Jeans. The new method requires just a fraction of the water we previously used, without compromising product quality. We do this by using special washing machines with ozone gas cleaning and nano-bubble cleaning functions. In addition, the introduction of eco-stones—long-lasting, artificial stones that do not wear down—has eliminated the need for crushed natural stones and reduced the amount of water required for cleaning.

*the amount of water used in the finishing process for GU’s Tapered Ankle Jeans as compared with conventionally finished products.

J Brand

Our Los Angeles brand is famous for its premium denim such as the Mid-Rise Super Skinny. The jeans are made of traceable cotton and recycled polyester, and are produced with technology to reduce water consumption in their finishing process.

-

-

Combating COVID-19

-

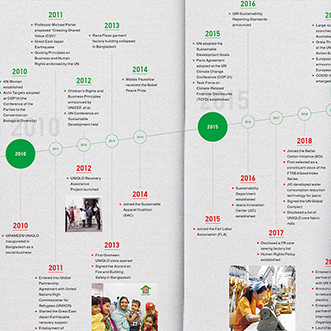

20 Years of Sustainability Progress

-

Gen Z : Changing the World

-

Caring for the Environment

-

Product Innovations

-

Helping Refugees Flourish

-

RE.UNIQLO:Rebirth of Clothes

-

Putting People First

-

Sport Meets Young Dreams

-

Giving Back to the World

-

Unlocking the Power

of Clothing -

Corporate Governance

-

FAST RETAILING WAY