OUR INITIATIVES FOR

THE ENVIRONMENT

MANAGING PRECIOUS

WATER RESOURCES

Making clothing that doesn’t waste or pollute water

Water is one of the most precious resources on Earth. At the same time, the clothing manufacturing industry requires a lot of it. A large volume of water is required to cultivate cotton as a raw material for garments, as well as for fabric dyeing and other parts of the production process. Fast Retailing is working to identify and solve local water-related issues across all processes, from sourcing raw materials to manufacturing and retail.

Conducting regular risk assessments across our value chain

We regularly conduct risk assessments throughout the value chain using the Aqueduct water risk assessment tool developed by the World Resources Institute. As part of that process, we have evaluated our core stores and offices, as well as the garment factories and fabric mills to which we outsource our production, and have identified facilities located in high-risk areas. A follow-up survey of the stores and offices in these high-risk areas has been conducted to ascertain information about the damage caused by past flood events, and the countermeasures that are currently in place. Through these company-wide management measures, we have achieved risk reductions. Additionally, we have conducted a survey of risk-assessed factories to establish actual water conditions in surrounding areas, and fluctuations in water prices. Through this survey we have identified factories with water risks, and are now working to further support them.

Preventing and reducing water pollution to address local issues and reducing water usage

Reducing water consumption

We are cooperating with regions that face high water supply risks, and with factories that use a lot of water, on numerous initiatives to reduce water consumption. We have set specific targets for each of our garment factories and fabric mills, which account for 80% of our total water consumption. Our overall aim is to reduce water consumption by 10% per unit of water used at each factory by the end of 2025 (vs. 2020 levels).

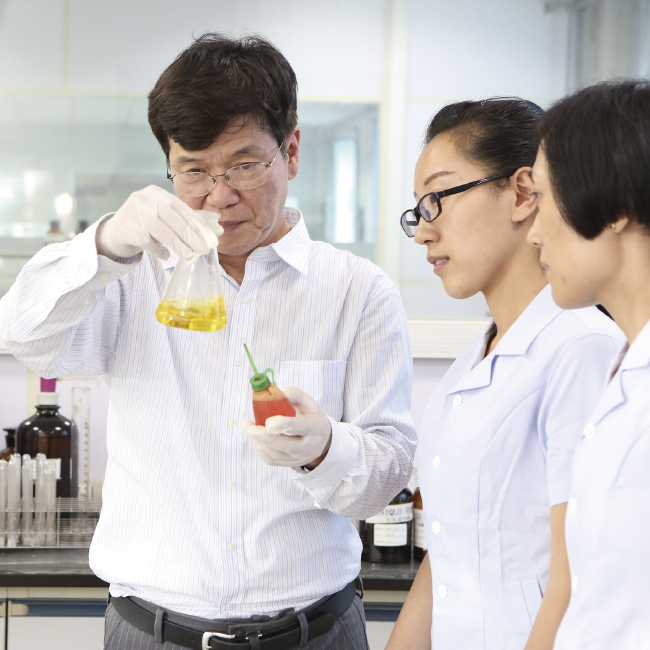

Introducing water-saving technologies

We are working with our production partners to encourage the development and introduction of water-saving techniques. Our BLUE CYCLE technology is one such example. BLUE CYCLE uses nanobubble washing and ozone cleaning to reduce significantly the amount of water used in the washing and processing of jeans. This technology has been introduced to the manufacturing process of jeans produced and sold by all brands of the Fast Retailing group. Fast Retailing is currently promoting the use of this initiative across all brands.

Ensuring appropriate wastewater treatment

Fast Retailing requires its core garment factories and fabric mills to conduct wastewater testing based on the Zero Discharge of Hazardous Chemicals (ZDHC) Wastewater Guidelines.(*1) Factories are then required to disclose their testing results on the Institute of Public & Environmental Affairs’ website, which is an environmental NGO based in China. If hazardous chemicals are detected in wastewater, we investigate the relevant factories and chemical manufacturers producing the offending substances to identify the root cause of any leaks. We also offer guidance to ensure that improvements are made. We aim to achieve zero pollution as determined through wastewater standards by the end of 2030.

*1 At the end of 2022, we had achieved 99% compliance with wastewater standards at our core garment factories and fabric mills.

Reducing water consumption in the production of raw materials

We seek to reduce water consumption by selecting raw materials at the product planning stage that require less water during production, and ensuring those materials are ultimately used. Furthermore, we aim to source 100% sustainable cotton across all Fast Retailing Group brands by the end of 2025. The definition of sustainable cotton includes a requirement to source cotton from areas where improvements in water usage have been made. We are also aiming to increase the proportion of recycled materials used to approximately 50% of total materials by fiscal 2030.

The definition of sustainable cottonMost Viewed Contents

-

PEACE FOR ALL

A SINGLE T-SHIRT HAS THE POWER TO SPREAD PEACE. “It’s time for action, in the name of world peace.” Major figures who share this vision with...

Read More

-

RE.UNIQLO STUDIO

Your UNIQLO clothes have a long life ahead of them. We're creating something positive for the future by keeping UNIQLO items in circulation....

Read More

-

UNIQLO DOWN RECYCLE

Recycling clothes into clothes, UNIQLO’s latest challenge that opens up new links between people, clothing, and the global environment. We are...

Read More

-

UNIQLO PRE-OWNED CLOTHES PROJECT by RE.UNIQLO

Once you’ve made the most of your clothes, it’s time to recycle. RE.UNIQLO is working towards a circular society by selling pre-owned clothes.....

Read More

Recommended Contents

-

RE.UNIQLO

Can your old clothing improve the future? Yes! At UNIQLO, we recycle your used garments through our circular sustainability programs. Take our recycled down ini...

Read More

-

JEANS INNOVATION

At the JEANS INNOVATION CENTER in Los Angeles, California, UNIQLO is rethinking the way that jeans are made by updating the methods...

Read More

-

GENDER

All women should be able to pursue their dreams and forge a new tomorrow. We want to see women enjoy infinite possibilities. Believe in a world that enables wom...

Read More

-

PREPARING CLOTHES FOR AN EMERGENCY DISASTER

UNIQLO has aided disaster victims around the world over the past 20 years. It has learned in the process that few people prepare clothing kits for such emergencies...

Read More

Newest Contents

-

CLOTHING MADE FROM RECYCLED MATERIAL

Our ability to recycle materials is growing as recycling technology evolves. New clothes made by recycling limited resources are becoming increasingly visible in UNIQLO’s product line-up...

Read More

-

UNIQLO PRE-OWNED CLOTHES PROJECT

Once you’ve made the most of your clothes, it’s time to recycle. RE.UNIQLO is working towards a circular society by selling pre-owned clothes.....

Read More

-

JEANS INNOVATION

At the JEANS INNOVATION CENTER in Los Angeles, California, UNIQLO is rethinking the way that jeans are made by updating the methods...

Read More

-

THE SETOUCHI OLIVE FOUNDATION

The Setouchi Olive Foundation is a not-for-profit organization established by world-renowned architect Tadao Ando and Kohei Nakabo....

Read More