Published on September, 2018 (from the power of clothes No. 20)

Sustainability in Jeans

Innovation is Transforming the Value of Jeans

Director

Jeans Innovation Center

Masaaki Matsubara

We set up our Jeans Innovation Center (JIC) in Los Angeles in November 2016 as a hub for jeans research and development tasked to transform the value of UNIQLO jeans.

The history of jeans began on the US West Coast, so the jeans making tradition, premium brands, top designers and latest information is concentrated in Los Angeles, the superior denim stronghold of today and yesteryear.

JIC is constantly exploring what jeans people want right now. Of course, we are always thinking about design, but design with sustainability in mind. How to develop wonderful jeans designs that don’t put a strain on precious water resources.

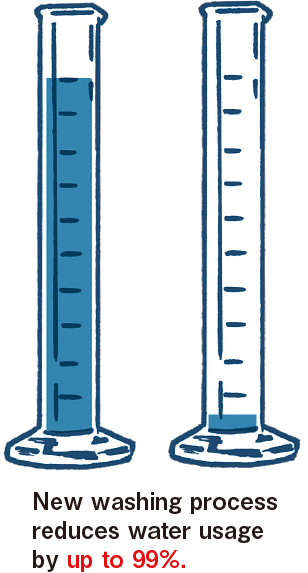

The jeans-washing process rinses finished pairs of jeans in large volumes of water. That in turn generates large volumes of wastewater. Jeans were originally forged out of American rationality, but producing them can cause an irrational amount of waste.”

Sustainability: Adding new value to jeans

When you live in Los Angeles, you choose clothes that are comfortable for you. It’s that rationality idea again. If you are hot, you take off your jacket. People instantly recognize clothes created with excessive expression by flamboyant designers, and don’t like wearing them.

It is the same with jeans. We want our jeans to be comfortable. No one decides jeans have to feel hard and coarse. People will embrace stretch light denim if it is comfortable. Jeans design and value are left to evolve rationally, because that is the nature of this place.

The same comfort-focused thought process applies to the environment. California is a dry land that doesn’t get much rain, so water is extremely precious. Using huge amounts of water in the jeans-making process is not a comfortable situation, so people do something about it fast.

Water resources are not the only issue. Take people working in the factory for instance. They have to apply and rub chemicals onto the surface of the jeans to create whiskers, or white stripes resembling cats’ whiskers on the upper thighs. Vintage processing such as creating holes used to be done by hand, but we now use new methods and technology to create more sustainable jeans.

Jeans are the product of rationality. We believe there are still many useful innovations we can make to improve jeans as much as the metal rivets introduced over 100 years ago.

The knowledge and information we need to do that is here in Los Angeles. It is JIC’s job to take advantage of those resources to explore and realize further innovations.